Sustainable Logistics for E-Commerce Brands: How Going Green Can Reduce Costs Without Slowing Delivery

If you run ecommerce delivery operations around London, you already know the trade-off people keep pushing on you: faster delivery, lower cost, and more sustainable delivery. Most teams assume you can only pick two.

In reality, many sustainability improvements are simply waste reduction. Waste shows up as failed first attempts, reattempt miles, packaging void, damaged parcels, WISMO tickets, and slow returns. When you remove waste, you usually cut cost and emissions while improving delivery experience.

This guide is built for operators shipping roughly 50 to 2,000 orders per day who want a practical way to make sustainable logistics work without slowing delivery.

What sustainable logistics means in e-commerce

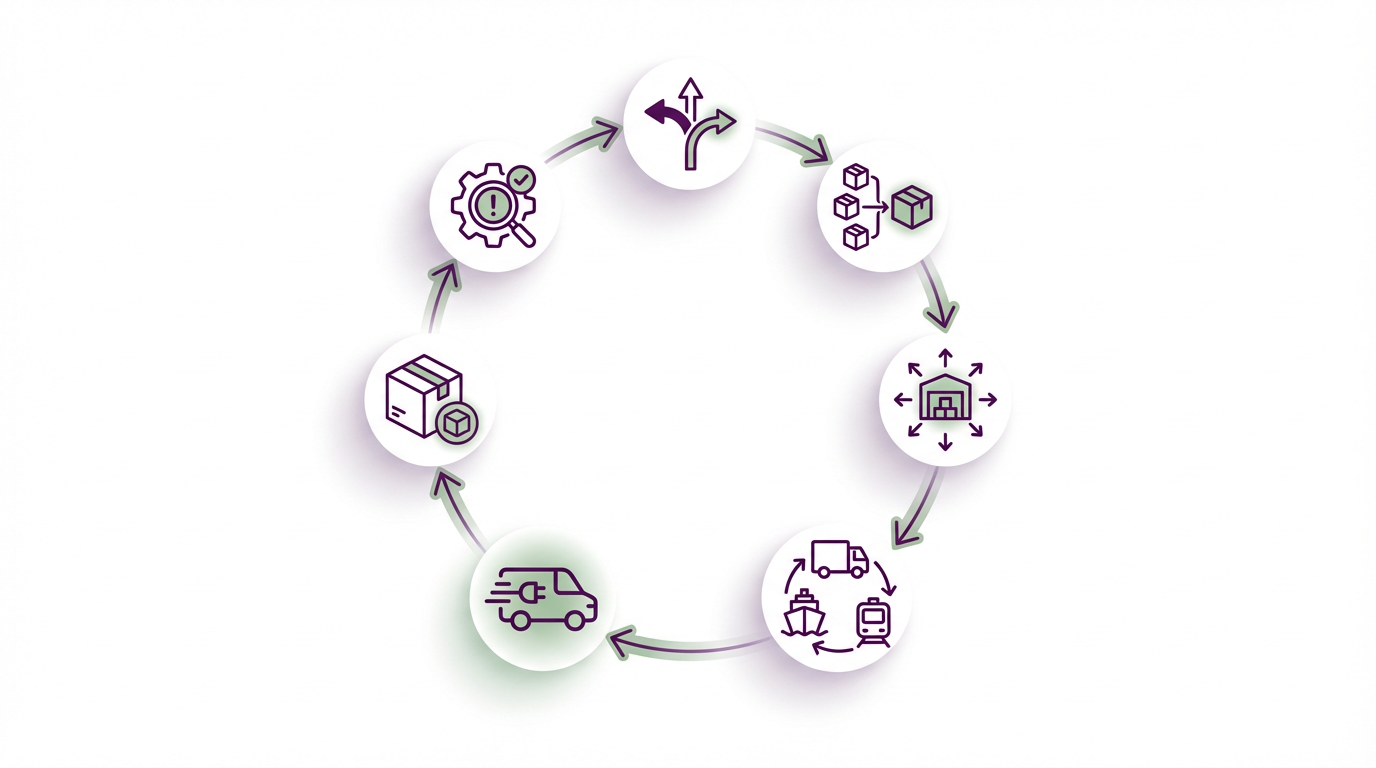

Sustainable logistics for e-commerce is not just eco-friendly packaging. It is the full delivery system: how you route, where you place stock, how you prevent failures, how you handle exceptions, and how you run returns so you do not pay twice. Packaging materials but it is only one lever in a larger chain.

Think of it as improving the quality of every delivery attempt. Fewer wasted miles, fewer avoidable touches, fewer failed deliveries, fewer returns loops. That is what lowers carbon footprint delivery impact and protects margins at the same time.

- Sustainable logistics: reducing waste and emissions across routing, fulfilment placement, delivery, packaging, and returns while protecting service levels

- Green delivery slot: a delivery option that helps consolidate drops into efficient routes, often via a wider time window

- Offsets vs insetting: offsets fund external projects, insetting reduces emissions inside your own logistics system

Is green delivery always more expensive?

It can be if you start with the wrong changes. The common mistake is buying “green” features before fixing the operational leaks. If your first-attempt success is weak, your routing is messy, and returns are slow, then any sustainability upgrade sits on top of a broken base.

A more useful lens is cost per delivered order. When delivery fails, you pay for extra miles, extra driver time, extra support, and often extra refunds and reships. When packaging is oversized, you pay volumetric charges and you increase damage risk. When returns move slowly, you lose cash flow and you risk stock-outs that create more emergency shipping.

The best approach is simple. Reduce waste first, then add upgrades where density and ROI make sense.

Seven ways to cut emissions and costs without slowing delivery

1. Smart routing and route optimisation

Route optimisation is one of the fastest ways to reduce miles without slowing delivery. Better routing improves drop density, reduces driver time, and increases first-attempt success. The key is to route around real delivery windows and traffic patterns, not only shortest distance. In dense areas, the most expensive routes are often the ones that look efficient on paper but create missed deliveries and reattempts.

2. Delivery consolidation and green delivery slots

Consolidation is a strong green logistics lever because it reduces avoidable travel. A green delivery slot works when you give the delivery network more flexibility to bundle drops efficiently, usually by offering a wider time window. Done correctly, this can improve reliability as well as sustainability because it reduces rushed attempts and repeated misses.

You can also add simple consolidation rules for multi-item orders so parcels are shipped together when it protects delivery speed and reduces packaging waste.

3. Distributed fulfilment and regional hubs

Distributed fulfilment protects speed because it reduces distance. If most orders are coming from London-area demand clusters, positioning fast-moving SKUs closer to those clusters reduces last-mile miles while keeping next-day delivery realistic. You do not have to rebuild your whole network. Start by testing a small regional placement for your highest-volume SKUs and measure cost per delivered order and on-time performance.

4. Multimodal transport for upstream moves

Last mile gets attention, but upstream transport often carries a large share of emissions. Where replenishment is planned, multimodal transport using rail or sea for parts of the journey can reduce emissions per unit moved and often stabilise costs. Road remains important for urgent moves, but multimodal becomes valuable once you can plan inventory movement with more predictability.

5. EV fleets and low-emission last-mile options

EV last mile works best where drops are dense and routes are predictable. In many London zones, density makes EV delivery viable, but the best results usually come from pilots first. Start with the postcodes where routes are consistent and utilisation will be high. Many operators also use a mixed approach so they can protect coverage and speed while expanding low-emission options over time.

6. Right-sized packaging and material swaps

Packaging is not just sustainability. It directly affects delivery cost, damage rates, and returns. Right-sized packaging reduces volumetric charges and improves vehicle utilisation. Better protective design reduces damage and reships. Once you have packaging fit and protection under control, material changes like recyclable or compostable options are easier to introduce without increasing returns.

7. Exception management and proactive comms

Exception handling is a quiet profit centre. Better exception management reduces WISMO tickets and reattempts, improves first-attempt success, and protects delivery speed. The practical work is often boring but effective: improve address quality, collect delivery instructions properly, send accurate delivery windows, and provide simple change options. Small improvements here can remove a lot of wasted miles.

Returns and reverse logistics, the hidden margin killer

Returns are one of the biggest sustainability and cost levers because they multiply transport and handling. A return is not just a customer event. It is another logistics cycle with more miles, more touches, and more support time.

The highest-impact approach is to consolidate and speed up. Consolidate returns where possible, set smart return rules that reduce unnecessary shipments, and speed up inspection and restock so inventory becomes sellable again quickly. If your category allows it, recommerce routes can reduce waste and recover margin by reselling items rather than writing them off.

Add asset here: A returns decision tree graphic showing the path from return request to inspect to restock, resale, refurbish, or recycle.

Technology that enables sustainable logistics and better ops

You do not need complicated systems to begin, but you do need visibility. Sustainable logistics becomes practical when you can see what is driving miles, failures, and returns.

Start by tracking delivery KPIs and cost KPIs, then layer basic carbon tracking using distance, vehicle type, and drops per route. Over time, better forecasting and analytics improves capacity planning, while RFID or IoT improves visibility and reduces losses and disputes. If you are selling into procurement-heavy environments, ISO 14001 alignment can act as a credibility signal.

The decision table operators actually use

This is worth keeping as a table because it helps stakeholders compare trade-offs quickly.

| Lever | What it improves | Cost | Speed | Emissions | Complexity |

|---|---|---|---|---|---|

| Smart routing | Miles, driver time, first-attempt success | High | Neutral to positive | High | Medium |

| Green delivery slots | Drop density, fewer reattempts | Medium to high | Neutral | Medium | Medium |

| Distributed fulfilment | Distance to customer | High | Positive | High | High |

| Multimodal upstream | Emissions per unit moved | Medium | Neutral | High | Medium |

| EV pilots | Last-mile emissions in dense zones | Medium with utilisation | Neutral | High | Medium |

| Right-sized packaging | Volumetric cost, damage | Medium | Neutral | Medium | Low |

| Exception management | WISMO, reattempts, refunds | Medium | Positive | Medium | Low |

A simple savings calculator for failed deliveries

If you want a fast business case, estimate what failed first attempts are costing you each month. Take your orders per day, multiply by the reduction you expect in failed first attempts, multiply by your average reattempt cost, then multiply by working days per month.

Even modest improvements often create meaningful savings because they remove repeat miles and repeat support work, and they reduce refunds and reships.

How to offer sustainable delivery options without hurting conversion

The goal is to give customers a choice that feels like a service upgrade, not a sacrifice. Green delivery slots often work when they are positioned as reliable delivery with fewer missed attempts. Locker pickup can reduce failures in dense areas. Consolidation can be offered as a default for repeat customers when it protects delivery experience and reduces packaging.

Testing matters. Run small tests by customer segment and measure conversion rate, first-attempt success, and support contact rate. In many cases, better reliability is the real conversion booster.

Implementation roadmap, 30, 60, 90 days

In the first 30 days, baseline your KPIs and take the quick wins: routing improvements, proactive comms, address quality, and packaging fit. These steps often reduce cost and emissions without slowing delivery.

By 60 days, implement consolidation rules, improve returns handling speed, and start simple monthly reporting that links operational changes to cost and delivery outcomes.

By 90 days, you can run pilots that require more coordination, such as EV last mile in dense postcodes, a small distributed fulfilment test for top SKUs, and multimodal planning for replenishment moves.

Choosing a sustainable logistics partner around London

When selecting a partner, focus on who can improve unit economics and delivery performance, not who uses the best sustainability language.

Use this short scorecard as a checklist:

- If you use COD, proven COD collection and reconciliation support

- Strong coverage around London for your key delivery zones

- Clear reporting on first-attempt success, on-time rate, and failed delivery reasons

- Routing and consolidation capability that protects speed

- Returns and reverse logistics support, including consolidation and fast processing

- Monthly reporting that links cost, delivery KPIs, and basic emissions

If you’re shipping ecommerce orders into London and nearby areas and you’re tired of rising delivery costs, failed first attempts, and WISMO, we can help. Tracked Transport supports ecommerce brands with reliable delivery operations, proactive tracking updates, and smoother exception handling so you can protect speed while reducing waste.

Questions E-Commerce Operators Ask About Sustainable Logistics

It is reducing waste and emissions across routing, fulfilment placement, delivery, packaging, and returns while protecting delivery speed and service quality.

Start with waste reduction through better routing, fewer failed deliveries, consolidation, proactive comms, and faster returns handling. These usually improve reliability.

Not always. Many sustainable changes lower costs because they reduce reattempts, support load, damages, and returns miles.

It is a delivery option that helps consolidate drops into efficient routes, often using a wider time window, which can reduce missed deliveries.

Returns add extra transport, labour, and support time and increase emissions. Consolidation and faster processing reduce both.

Cost per delivered order, first-attempt success, on-time rate, failed delivery reasons, WISMO volume, returns cycle time, and a basic emissions baseline.

Offsets fund external emissions reduction projects. Insetting reduces emissions inside your delivery and fulfilment operations through changes like routing, consolidation, EVs, and packaging.

They work best on dense routes with predictable mileage and high utilisation, usually starting with a pilot in high-volume postcodes.

Delivery KPIs, cost KPIs, exception reasons, returns performance, and a basic emissions view tied to actual operational data.