E-Commerce Returns Logistics Best Practices, How Tracked Transport Helps Returns Run Smoothly

Returns can undo a great delivery experience. When the process is slow or unclear, customers ask for updates, your team wastes time chasing status, and inventory sits off-sale for longer than it should. Over time, that hits margin and it chips away at trust.

This page is a practical guide to e-commerce returns logistics. It covers what a strong returns setup looks like, where costs usually creep in, and what to ask when you are choosing a logistics partner. It also explains how Tracked Transport supports returns with a focus on reliability, visibility, and operational control.

What e-commerce returns logistics actually includes

Returns logistics is the system that moves items back into your control and keeps the journey visible end-to-end. It is different from a returns policy. A policy sets expectations. Logistics is what makes those expectations real.

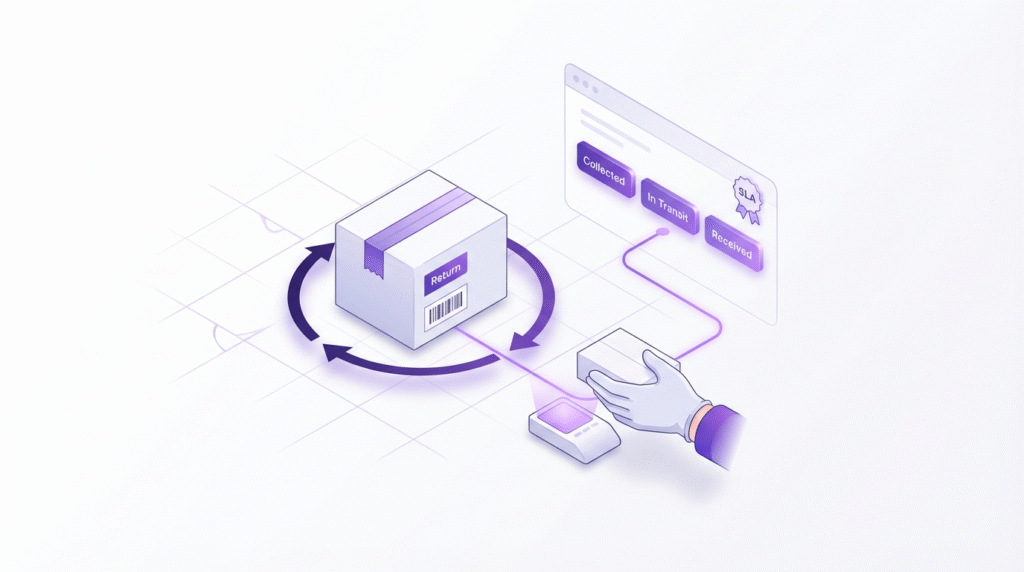

A return should follow a simple flow. The return is created. The item is handed over through collection or drop-off. It moves back through the network. It reaches your destination point. Then it is ready for the next action, like restocking, exchanging, or refunding.

When that flow is reliable, returns stop feeling like daily disruption. They become a process you can manage and improve.

A quick returns health check

If returns feel messy, this short check usually shows why.

- You can estimate cost per return with confidence

- The team can see where a return is without internal chasing

- You have proof of handoff through proof of collection or a clear drop-off record

- Exceptions follow a consistent rule, not ad hoc escalation

- Returns come back fast enough to protect resale value and stock availability

If two or more points are not true, you do not need more effort. You need a better system.

Why returns get expensive fast

Returns rarely get expensive because of one big failure. Costs build up through small gaps that create rework, delays, and uncertainty.

Missed collections lead to repeat attempts. Weak tracking forces manual investigation. Slow inbound flow pushes out the refund timeline and drives support contacts. Unpredictable arrival patterns create processing backlogs. Over time, these gaps increase shrink and reduce resale recovery.

If you want a simple measurement window, track these for two weeks. Count repeat collection attempts. Count returns-related support contacts. Check how often the tracking trail is missing key scan events. Those three numbers usually explain most of the pain.

Best practices that make returns faster, cheaper, and easier to manage

A strong returns setup is not about perfection. It is about consistency and visibility.

1. Capture return reasons your operations team can use

Return reasons are only useful if they lead to action. Keep them simple. Review patterns weekly and fix root causes. Packaging issues, listing clarity, and product quality usually show up fast when reason codes are clean.

2. Make handoff reliable

Most friction starts at the handoff. Reliable collections reduce missed pickups and repeat attempts. That improves cycle time and protects customer trust.

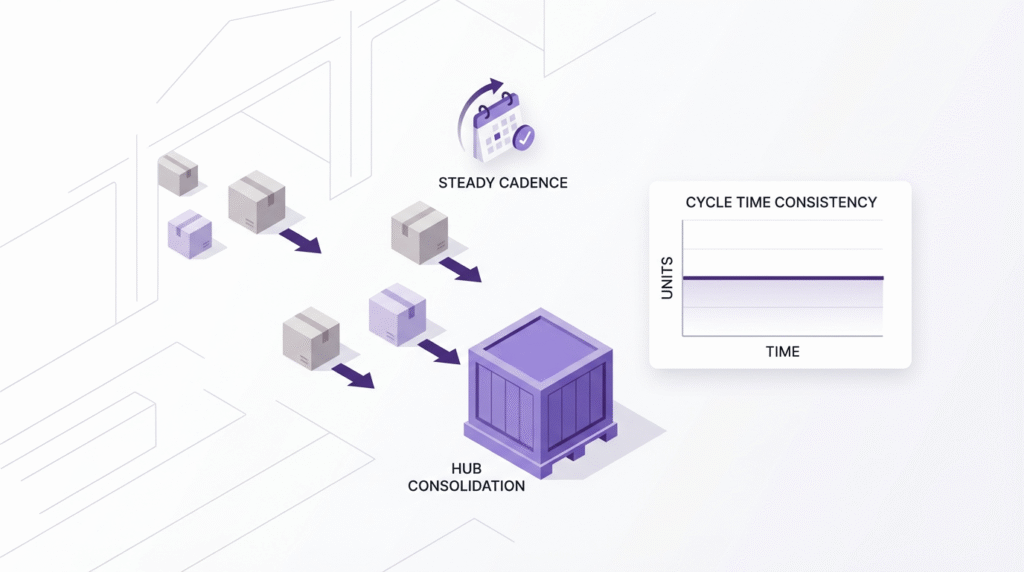

3. Use consolidation when volume supports it

As return volume grows, sending every item back as a standalone movement can inflate cost per return. Consolidation can reduce per-unit cost and it can make inbound more predictable. Some brands use a consolidation hub model, others rely on scheduled linehaul back to a main point. The right approach depends on volume and cadence.

4. Define tracking milestones your team can act on

Tracking should support decisions, not just provide a final delivered scan. Your team needs milestones that show progress and highlight delays early.

5. Create an exceptions playbook

Exceptions happen. The difference is whether you handle them consistently. Decide what happens when a pickup is missed, when an item arrives damaged, or when the wrong item is returned. Keep escalation clear and time-bound so issues do not drift.

6. Speed up inbound verification

Many brands lose money because returns arrive and sit. Faster check-in protects resale value. It also reduces refund friction and improves inventory availability. This is where inspection and grading discipline matters.

7. Keep chain of custody clear

You do not need a heavy process. You do need a clear chain of custody, plus scan events that show where the item is and when it moved. This reduces disputes and helps you spot patterns that look like returns fraud.

Returns tracking that reduces tickets and protects trust

Returns tracking should reduce customer uncertainty and reduce internal workload at the same time.

When tracking is strong, support can answer questions quickly. Operations can forecast inbound and spot delays early. Finance can rely on a clear trail when timelines are questioned. Customers notice predictability, even when they would rather not be returning an item.

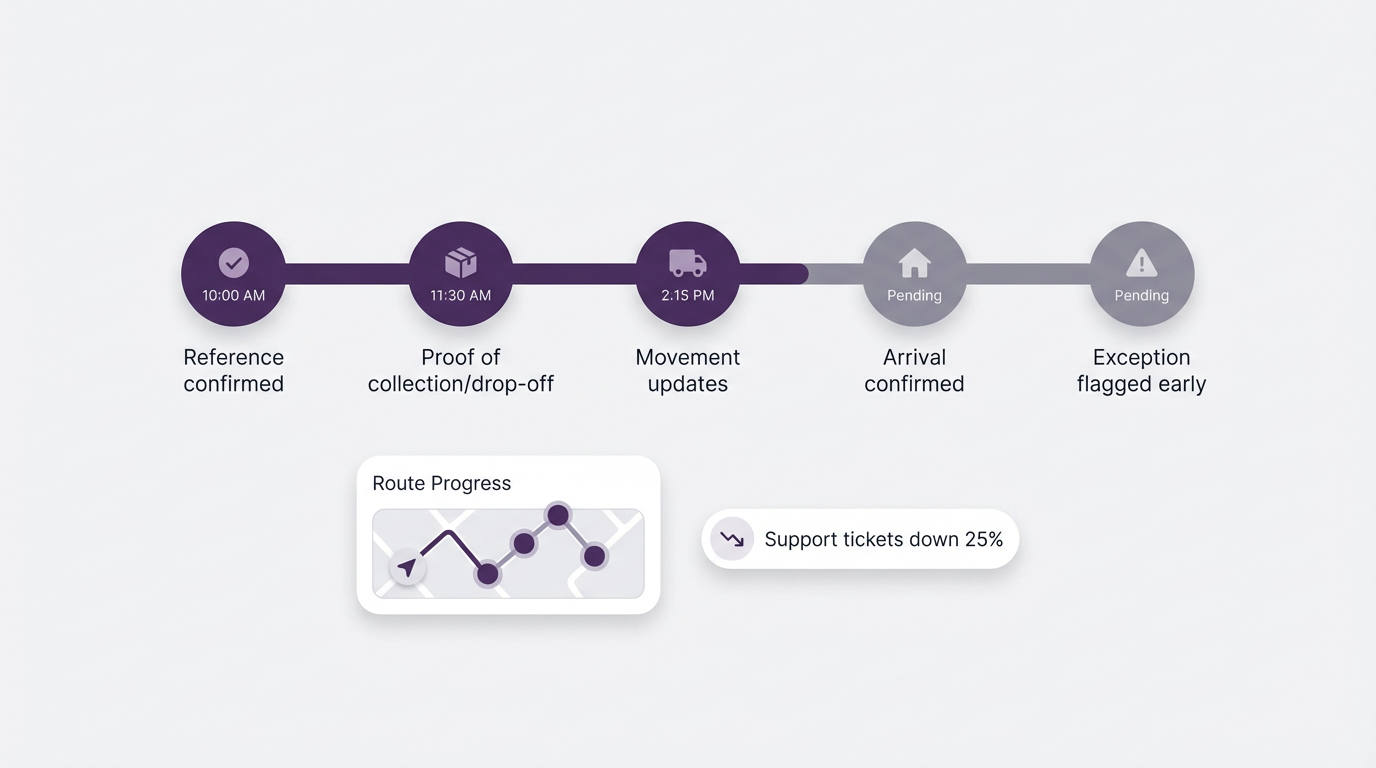

A practical baseline includes these milestones.

- Return reference confirmed, including RMA where relevant

- Handoff confirmed with proof of collection or drop-off

- Movement updates that show progress through the network

- Arrival confirmed at the destination point

- Exceptions are flagged early when something goes off track

If your current setup cannot provide those reliably, you will keep paying for uncertainty.

Consolidation and cycle time

Consolidation is often discussed as a cost tactic. It also improves predictability. Predictable inbound reduces processing chaos and it helps keep cycle time stable.

Cycle time matters because it affects refund and exchange timelines, stock availability, and resale value. Even if your target varies by category, stability is the key. Stable timelines support better staffing and clearer customer communication. They also reduce escalations.

A simple rule helps here. If returns are steady week to week, consolidation is easier to plan. If returns are rare, it may not be worth the overhead.

What to ask a returns logistics partner

Broad questions lead to broad answers. If you want clarity, ask questions that map directly to speed, cost, and visibility.

- Which tracking milestones will we see, and how quickly do updates appear

- What proof of collection is available, and how is it shared

- How are missed collections handled, and what is the escalation path

- How do you flag exceptions early, and what happens next

- What weekly KPI reporting do we receive, and which metrics are standard

- What is your approach to returns consolidation when volume supports it

- What does onboarding look like, including onboarding SOP alignment

- What service level can you commit to, including an SLA for exceptions

How Tracked Transport supports faster returns, lower costs, and clearer visibility

A good partner outcome should be easy to explain and easy to measure. Faster cycle time. Lower cost per return. Tracking that reduces confusion and support contacts.

Tracked Transport supports returns by focusing on reliability at handoff, consistency through the flow, and visibility that helps teams act early. When handoffs are dependable, returns stop stalling. When exceptions follow clear rules, delays are shorter and easier to manage. When tracking milestones are timely, your team spends less time investigating and more time operating.

Returns also need a clear endpoint. Once items arrive, the next step should be obvious. Restock when the item is clean. Refurbish when recovery makes sense. Recycle when it does not. Clear disposition decisions reduce backlog and protect margin.

A simple rollout plan that reduces switching risk

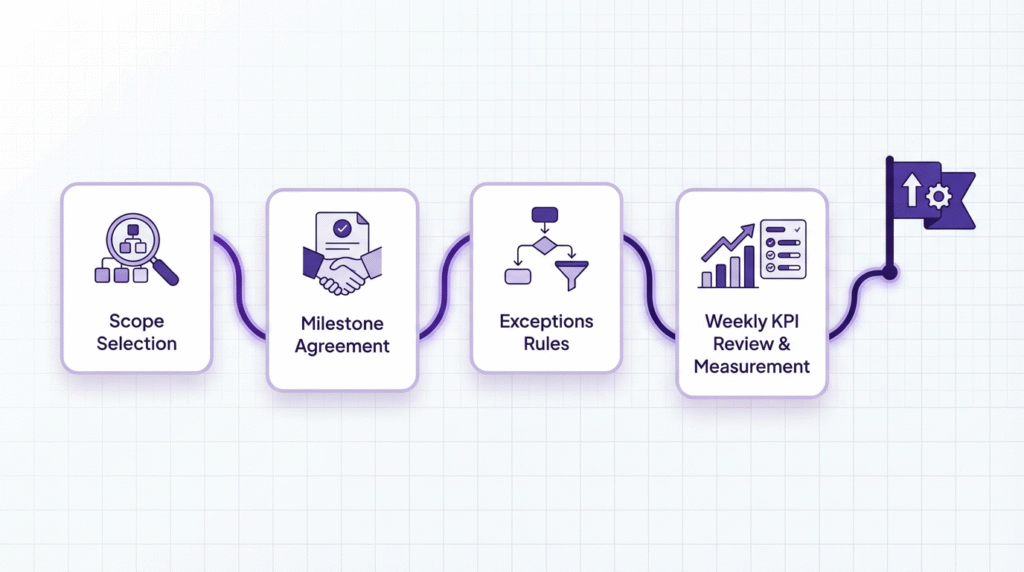

Switching logistics support can feel risky when the steps are unclear. A structured pilot reduces that risk and gives you proof before you scale.

A practical pilot usually looks like this.

- Choose a clear starting scope and expected weekly volume

- Agree the tracking milestones your team needs

- Define exception categories and escalation rules

- Review results weekly using a small KPI scorecard

After the pilot window, compare cycle time, cost per return, exception rate, and time spent chasing status. If the flow is stable, scaling becomes straightforward.

Returns KPIs worth tracking

You do not need dozens of metrics. You need a scorecard that reflects speed, cost, and reliability.

- Cost per return

- Collection success rate

- Cycle time from initiation to received

- Exception rate and top causes

- Tracking milestone timeliness, meaning updates appear fast enough to help

- Time to action on exceptions

- Shrink and mismatch rate, where you can measure it

If you already run a weekly ops review, add returns as a standing topic. A short check on cycle time, exceptions, and root causes is often enough to keep improving.

Final takeaway and next step

Returns do not have to feel like constant damage control. When the flow is reliable and visibility is clear, customers get predictable outcomes, your team stays in control, and costs are easier to manage.

If you want to tighten your current setup, start with a returns review focused on cycle time, cost per return, tracking milestones, and exception handling. A pilot is often the cleanest way to prove improvement before you scale.

Returns logistics FAQs for e-commerce brands in London

It is the operational system that moves items back into your network and keeps the journey visible with clear handoff records, tracking milestones, and consistent exception handling. It is what makes your returns policy workable at scale.

Reverse logistics is the broader category. Returns are one part of it. Reverse logistics can also include repairs, refurbishments, and recovery workflows.

By reducing rework and uncertainty. Fewer missed collections, clearer scan events, faster exception handling, and a more predictable inbound flow typically lower cost per return over time.

At minimum, you want a confirmed return reference, proof of collection, movement updates that show progress, and confirmed arrival. Those milestones reduce disputes and help your team act early when something goes off track.

It usually makes sense when return volume is steady enough to plan a consistent cadence, and when cost per return is rising. It can also help when inbound processing is unpredictable and you need a steadier flow.

Start with clear handoff rules and a consistent scheduling approach, then track collection success rate weekly. When misses happen, early exception flags and a clear escalation path prevent delays from stretching out.

Focus on tracking milestones, proof of collection, exception handling, KPI reporting cadence, consolidation capability, and onboarding process. Those answers tell you far more than broad coverage claims.

It can help. Clear chain of custody, proof of collection, and consistent scan events make it easier to spot anomalies and resolve disputes quickly.